retour

The landscape of the European packaging industry is currently evolving, with the new Packaging and Packaging Waste Regulation, which has been voted through and will soon be applicable in every member country of the European Union.

In this context, BUDDIE-PACK, founded by the European Union, aims to develop and demonstrate sustainable strategies for reusable plastic packaging in the food and cosmetics & personal care sectors, in order to meet the new regulations requiring the introduction of reusable packaging on the market.

Knauf Industries is a key player in the European BUDDIE-PACK project, launched on September 21 and 22, 2022 in Oyonnax, France. This project, funded by the new Horizon Europe program, is coordinated by the Centre Technique Industriel des Plastiques et Composites (IPC) and brings together 19 partners from six different countries. With a budget of almost 7 million euros, the project will run for three and a half years.

Six specific targets have been set for implementing reusability. They cover all aspects of the subject. Technological solutions are developed for the design and manufacture of packaging to meet the functional properties required and appropriate for reuse. Consumer expectations are analyzed to better understand the drivers and barriers to behavioral change.

Sustainable business strategies offering profitable economic models for reusable plastic packaging are developed. Consumer and product safety, risk management and reducing the release of microplastics into the environment are key parameters taken into account.

Large-scale trials are carried out to validate reusable plastic packaging along value chains from a technical, economic and social point of view. The promotion of reusable plastic packaging throughout the EU is part of the program.

Knauf Industries, as a specialist in packaging solutions and technical parts for various sectors such as food and industry, plays a crucial role in this project, contributing to the various case studies by participating in the technical definition of the packaging and its production.

With an international presence assured by 38 plants worldwide, we master several technologies: foam molding (EPS and EPP), custom foam cutting, extrusion, thermoforming and plastic injection (PP, CPET and PBT).

By actively participating in BUDDIE-PACK, Knauf Industries is committed to revolutionizing the packaging industry while respecting environmental standards and meeting its customers’ needs with advanced, sustainable solutions.

Stay tuned, until the end of 2024, to discover the products manufactured for this project.

Knauf Industries has made innovation a central part of its CSR policy. Working with our partners, customers and suppliers, we strive to develop products and materials that promote the circular economy.

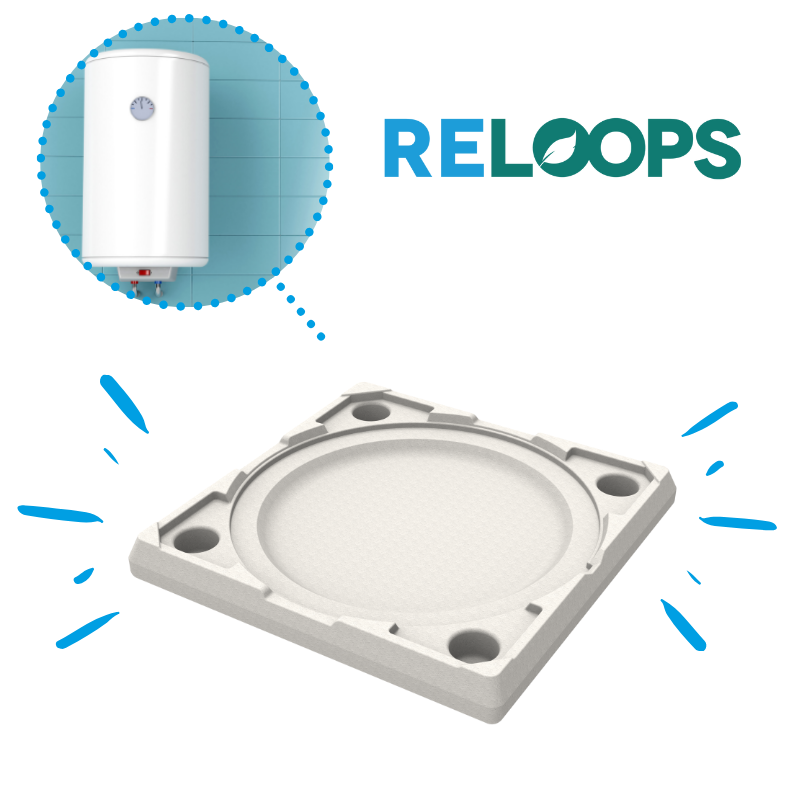

Working closely with its customer and supplier partners, Knauf Industries has launched RELOOPS®, a range of cellular material solutions as an alternative to petroleum-based expanded polystyrene, made from pre- and post-consumer waste polystyrene (PS) and expanded polystyrene (EPS).

As part of its CSR policy, Knauf Industries continues to innovate for a circular economy by offering materials derived from renewable or recycled resources as an alternative to petroleum-based materials, thus reinforcing its commitment to the preservation of fossil resources.

“As part of its CSR (Corporate Social Responsibility) policy, Knauf Industries has set itself the target of offering its customers materials derived from renewable or recycled resources as an alternative to petroleum-based materials by 2025. With the launch of RELOOPS®, we are demonstrating our commitment to reducing our environmental impact while meeting the needs of the market”

Patrick Sutter, Innovation Director

Called RELOOPS®, this new material solution offers characteristics comparable to those of fossil-based expanded polystyrene (thermal and mechanical resistance, shock absorption, etc. on request), while incorporating recycled polystyrene from the mechanical recycling of pre- and post-consumer polystyrene (PS) and expanded polystyrene (EPS) waste.

This approach not only helps reduce waste, but also conserves fossil resources.

RELOOPS® is just as recyclable as fossil-based EPS, in existing channels including Knauf Circular®. RELOOPS® is ideally suited to industrial packaging*, technical parts and insulation products.

The recycled content of RELOOPS® products is certified by REDcert².

*For packaging, the use of materials containing post-consumer waste entitles the user to an eco-contribution premium, subject to the eligibility conditions of the eco-organizations (please consult us). RELOOPS® is not suitable for food contact.

In addition to RELOOPS®, Knauf Industries already offers other alternative material solutions: NEOPS®, CELOOPS® and R’KAP®.

– NEOPS® : a certified1 material solution made from raw materials sourced from sustainable renewable resources2 and manufactured using the biomass balance approach. Its characteristics are identical to those of virgin EPS, but with a reduced carbon footprint.

– CELOOPS® : a certified material solution made from up to 100% raw materials derived from the recycling of post-consumer plastic waste, manufactured using the mass balance approach. Its characteristics are identical to those of virgin EPS.

– R’KAP® : mono-material suitable for packaging food products, certified to be derived from up to 100% post-consumer plastic recycling. Formulated on a polypropylene PP base, it is intended for the manufacture of thermoformed or injected products.

With this product, Knauf Industries is developing an alternative to fossil-based virgin polypropylene (PP).

In short, these new solutions developed for Knauf Industries customers open up new prospects for the circular economy and the preservation of fossil resources, while offering viable alternatives to traditional EPS, PP and soon PPE materials.

Please do not hesitate to contact us for further information.

¹certified by REDcert²

²Biomass from industrial waste unsuitable for food use or organic waste (organic waste from the forestry industry, not involved in deforestation, no competition with agricultural land for food production). Directive (EU) 2015/1513), Annex IX, Part A

It’s been a tumultuous year, marked by many serious economic and social challenges.

Knauf Industries has had to adapt to a constantly changing environment in the countries and markets in which we operate.

In this context, as an industrial company, the safety of all our employees and sustainable development are our two priorities.

Our ambition for 2024 is to strengthen our Health & Safety policy through the implementation of the dedicated “Kenza” plan, aimed at achieving a Zero Accident objective.

With the involvement of everyone, “Kenza” will address all the crucial and fundamental aspects of safety in the workplace.

Guided by our vision and mission, we continue to take action to achieve our sustainability goals. A major challenge for our markets and for us as a company is to find our role in decarbonizing our processes, and to help our business partners do the same.

In 2024, we are continuing our commitment in this direction.

➡ Our main areas of focus in 2024 will be,

We would like to express our deepest gratitude to each and every member of our involved team. Thank you for your unfailing commitment!

To our customers and partners, we thank you for your renewed confidence. We look forward to continuing our collaboration. May this end-of-year period bring you calm and happiness.

We wish you a successful year in 2024.✨

The Knauf Industries team